- Home+Product

TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.comHot+About BOB-LIFT

TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.comHot+About BOB-LIFT TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.comApplication+Service

TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.comApplication+Service TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.comNews

TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.comNews TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.com

TERMS & CONDITIONS OF SERVICESAMPLE ORDER: EMAIL: WHATSAPP/WECHAT: ADD:Amelia info@boblift.com +86-15852499415 Building 1-1008, 1009, Nandu Business Center, No. 5, Quanshan District, Xuzhou City, Jiangsu Province, ChinaDealer Business :business@boblift.com

BOB-LIFT Teaches You To Connect The Brick Grabber Correctly To Unleash High Productivity

Views: 0 Author: Site Editor Publish Time: 2025-12-23 Origin: Site

Step 1: Preparatory work - Security and compatibility checks

Confirm compatibility: First, ensure that the hydraulic system parameters (flow rate, pressure) of your BOB-LIFT folding boom crane are exactly matched with the requirements of the brick grabber. Each of our devices is equipped with a clear technical manual. Please be sure to check it.

Check the "hands" : Carefully inspect the hydraulic cylinder, pin shaft, locking mechanism and hydraulic quick coupling of the brick-grabbing machine fixture to ensure there is no deformation, wear or blockage. At the same time, inspect the rotary joint or connecting plate at the end of the crane boom.

Prepare the necessary tools: Get ready suitable pins, safety lock plates/cotter pins, grease guns (for lubricating pins), and essential personal protective equipment.

Step Two: Mechanical connection - Stability is fundamental

Alignment and insertion: Precisely align the connecting ear plate at the top of the brick grabber with the connecting plate at the end of the crane boom. Insert high-strength alloy pins. Remember, the pin shaft is the core load-bearing component and must use the original equipment or matching grade accessories.

Locking safety: After inserting the pin shaft, immediately install the safety lock plate or cotter pin and fully pry it apart to lock it in place to prevent the pin shaft from accidentally coming out due to vibration. This is a crucial step in preventing major safety accidents!

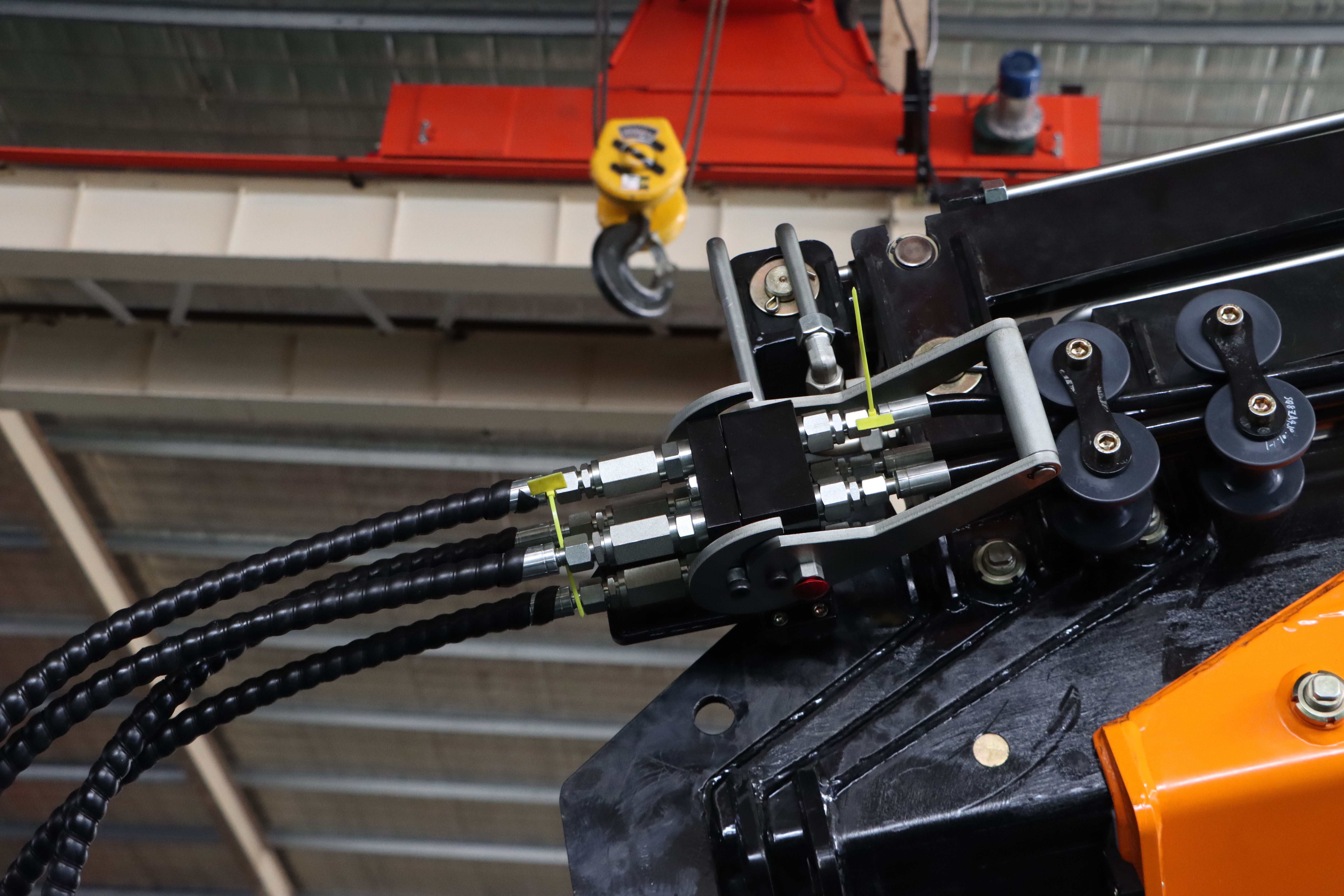

Step 3: Hydraulic Connection - Giving It "Life"

Clean the connector: Before connecting the hydraulic quick connector, wipe the male and female connectors with a clean cloth to ensure there is no dust or impurities. Even a grain of sand or dust can damage the precision valve core, causing internal leakage or jamming in operation.

Quick connection: Align the hydraulic pipe quick connector of the brick grabber with the corresponding connector extending from the crane boom (usually controlling the opening, closing and rotation of the fixture), and push it in with force until a "click" locking sound is heard. Do not connect or disassemble under pressure!

Step 4: After connection, debug and conduct a trial run

No-load test: Start the crane engine, operate the pilot handle, and slowly test all the opening, closing, and rotation (if any) actions of the brick grabber. Observe whether the movement is smooth and stable, and whether there are any abnormal noises or lag.

Pressure testing and fine-tuning: Under no-load conditions, let the brick grabber perform several fully open and fully closed cycles to expel the air in the hydraulic pipeline. Check whether there is any oil leakage at each joint.

Load test: When picking up bricks for the first time, start with the lightest load, operate slowly, and feel the force and control accuracy. After confirming that the clamping is firm and there is no slippage, normal operation can be carried out.

BOB-LIFT Professional Tips:

Daily lubrication: Before each connection, apply grease to all connecting pins to reduce wear and extend service life.

Sealing inspection: Regularly inspect the O-rings at the hydraulic joints. Replace them immediately if any signs of aging or damage are found.

Human-machine integration: Skilled operators combined with stable equipment form the most efficient combination. It is recommended to conduct specialized operation training.

The correct connection is the starting point of security and efficiency. BOB-LIFT, not only provides reliable equipment, but also is willing to be your trustworthy partner to jointly build every solid structure.